The Mercedes diagnostic system, a complex network of software and hardware, monitors and maintains vehicle performance. This system is crucial for accurate Mercedes repair, enabling professionals to enhance performance, improve safety, and extend vehicle lifespan. Integrating advanced diagnostic tools in collision repair centers enhances efficiency, quality, and customer satisfaction, especially for complex repairs like hail damage or paintless dent repair. The Mercedes Certified Collision workflow leverages this system for fender and bumper repairs, streamlining processes, reducing downtime, and preserving Mercedes' craftsmanship, despite the resource-intensive training and quality control required.

The Mercedes diagnostic system is a cornerstone of the brand’s certified collision workflow, revolutionizing repair processes. This advanced technology offers precise insights into vehicle conditions, enabling efficient and accurate repairs. In this article, we’ll explore the basics of the Mercedes diagnostic system, its seamless integration into collision repair, and the multifaceted benefits it brings. We’ll also delve into potential challenges and how certified collision centers harness these systems for optimal results.

- Understanding Mercedes Diagnostic System Basics

- Integrating Diagnostics into Collision Repair Process

- Benefits and Challenges of Certified Collision Workflow

Understanding Mercedes Diagnostic System Basics

The Mercedes diagnostic system is a complex network designed to monitor and maintain the performance and integrity of Mercedes Benz vehicles. At the heart of this system lies advanced software and hardware that work in harmony to detect issues, diagnose problems, and provide real-time data to both the vehicle’s computer and trained technicians. This sophisticated mechanism covers everything from engine management and transmission control to braking systems and body structural integrity.

Understanding how this diagnostic system operates is crucial for anyone involved in mercedes benz repair or vehicle repair in general. It enables precise identification of faults, facilitates efficient frame straightening processes, and ensures that each repair is executed with meticulous accuracy. By leveraging the Mercedes diagnostic system’s capabilities, professionals can enhance overall vehicle performance, improve safety features, and extend the lifespan of these high-performance machines.

Integrating Diagnostics into Collision Repair Process

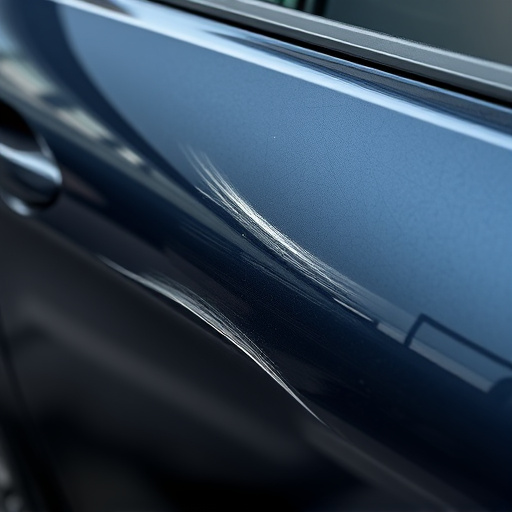

Integrating diagnostics into the collision repair process is a game-changer for any Mercedes collision center. The Mercedes diagnostic system plays a pivotal role in this transformation, offering precise and comprehensive insights into vehicle conditions. By seamlessly incorporating advanced diagnostic tools, technicians can efficiently navigate through complex repairs, from identifying subtle issues to assessing extensive hail damage repair or paintless dent repair needs.

This streamlined approach ensures that every repair is tailored to the specific Mercedes model, maximizing efficiency and quality. With real-time data at their fingertips, collision center folks can make informed decisions, enhancing customer satisfaction. Moreover, the Mercedes diagnostic system’s ability to detect intricate problems early on can prevent costly misdiagnoses, fostering a reputation for reliable and precise work.

Benefits and Challenges of Certified Collision Workflow

The Mercedes Certified Collision workflow integrates a sophisticated Mercedes diagnostic system that offers several benefits for both vehicle owners and collision repair specialists. By leveraging advanced technology, this system ensures precise assessments and repairs for various car models. It streamlines processes like fender repair and bumper repair, minimizing downtime and maximizing efficiency. The diagnostic tool provides real-time data on parts compatibility, repair techniques, and factory specifications, enabling technicians to perform high-quality collision repair that meets Mercedes’ stringent standards.

However, implementing this certified collision workflow comes with its challenges. It requires specialized training for technicians to operate the Mercedes diagnostic system effectively. Additionally, adhering to strict quality control measures can be resource-intensive and demand continuous investment in updates and calibration of the diagnostic tools. Despite these challenges, the benefits of a streamlined, technology-driven approach to collision repair far outweigh the obstacles, ultimately enhancing customer satisfaction and ensuring the preservation of Mercedes’ renowned craftsmanship.

Mercedes’ advanced diagnostic system plays a pivotal role in streamlining collision repair processes, ensuring precision and quality. By seamlessly integrating diagnostics into their certified collision workflow, workshops can benefit from faster identification of issues, reduced repair times, and enhanced customer satisfaction. While there may be challenges in implementing this system, the advantages for both technicians and vehicle owners are significant, making it a valuable asset in modern automotive servicing.